TruckElectric

Well-known member

- First Name

- Bryan

- Joined

- Jun 16, 2020

- Threads

- 609

- Messages

- 2,004

- Reaction score

- 1,493

- Location

- Texas

- Vehicles

- Dodge Ram diesel

- Occupation

- Retired

- Thread starter

- #1

Volvo Penta Starts Production Of E-driveline For EV Fire Truck

Rosenbauer “Revolutionary Technology” (RT) is the world’s first serial electric fire truck.

Volvo Penta (part of Volvo Group) announced that it has commenced production of bespoke electric drivelines for world’s first serial electric fire truck - Rosenbauer’s “Revolutionary Technology” (RT).

The Swedish company has adapted EV technology from Volvo Trucks and Volvo Buses to create a dedicated setup for the RT, which utilizes a completely new vehicle architecture.

The vehicle uses a dual-motor all-wheel-drive system and a six-cylinder diesel engine in case the 50 kWh or 100 kWh battery runs out of electricity.

So far, only a few units were built and entered pilot service in Berlin, Amsterdam, and Dubai, as well as were demonstrated around the world, including in the U.S.

It will be very interesting how well the electric fire trucks will cope in the real world as it's a much more demanding application than an ordinary electric truck. This is also why there is still an onboard diesel generator.

Rosenbauer’s electric fire truck “Revolutionary Technology” (RT) specs:

SOURCE: INSIDEEVs

Mantsinen Dualpower combines electric, diesel motors

The Mantsinen Dualpower material handler promises mobility, productivity and environmental friendliness.

July 9, 2021

Posted by DeAnne Toto

Posted by DeAnne Toto

The Mantsinen Dualpower material handler combines what the manufacturer says are the best features of electric and diesel engines, resulting in mobility, productivity and environmental friendliness.

Swedish company Engbergs Transportsystem AB operates at Östrand pulp mill, near the Sundsvall port on the Swedish east coast. The company is offloading of round wood and woodchips and also has started handling bark. Engbergs has a long history with Mantsinen Group.

Kjell Arne Engberg, CEO of Engbergs, says, “Our relationship with Mantsinen has deepened during the years. In 2003, our first Mantsinen machine was put to use, and we were very satisfied with the machine, not to mention the service support we got. No ma tter where in the world our contact was, they always answered the phone.”

In 2017, Engbergs began discussing Mantsinen’s latest innovation, the Dualpower material handler, with the manufacturer. Engbergs was the first customer to acquire a Mantsinen’s Dualpower machine: a Mantsinen 120 with crawler gantry undercarriage.

“I am very open-minded towards development of new technology,” Engberg says. “We purchased one diesel Mantsinen 120 and one Mantsinen 120 with Dualpower. The reason for the machine renewal l was that the pulp mill decided to increase production by 100 percent, and we needed to solve the logistics accordingly. In all our investments, we look into the possibility of reducing carbon emissions. We wanted this solution because it combines two benefits: when you reduce emissions, you also reduce costs. It is a win-win situation. However, we still needed a diesel-driven machine too, because we could not access electrical power all around the pulp mill area. The pulp mill was luckily very interested in helping us build the power grid solution.”

One of the benefits of the Dualpower material handler is easy maintenance, the manufacturer says. The technology is based on standard components, allowing easy service and normal spare parts availability. Pairing this technology with the Mantsinen Insight remote monitoring system allows smooth operation and fewer unexpected surprises, Mantinsen says.

The material handler works well, and it has reduced the need for maintenance,” Engberg says. He adds, “The Mantsinen Insight lets the machine tell you if something is not right. In the future, I think we could even solve some problems remotely and not on the site.”

In addition to maintenance needs, the Mantsinen Insight also records important data on performance and efficiency. Engbergs has achieved the production increase it wanted with the help of the Mantsinen 120 Dualpower.

“Looking at the last 7 days, we have lifted 23 000 [metric tons] mainly running on electric motor. Our production has been in average 435 [metric tons] per hour.”

He adds, “It seems this material handler with both diesel and electric drive is the right solution for us. We have reduced the emissions enormously.”

https://www.recyclingtoday.com/article/mantsinen-dualpower-material-handler/

Rosenbauer “Revolutionary Technology” (RT) is the world’s first serial electric fire truck.

Volvo Penta (part of Volvo Group) announced that it has commenced production of bespoke electric drivelines for world’s first serial electric fire truck - Rosenbauer’s “Revolutionary Technology” (RT).

The Swedish company has adapted EV technology from Volvo Trucks and Volvo Buses to create a dedicated setup for the RT, which utilizes a completely new vehicle architecture.

The vehicle uses a dual-motor all-wheel-drive system and a six-cylinder diesel engine in case the 50 kWh or 100 kWh battery runs out of electricity.

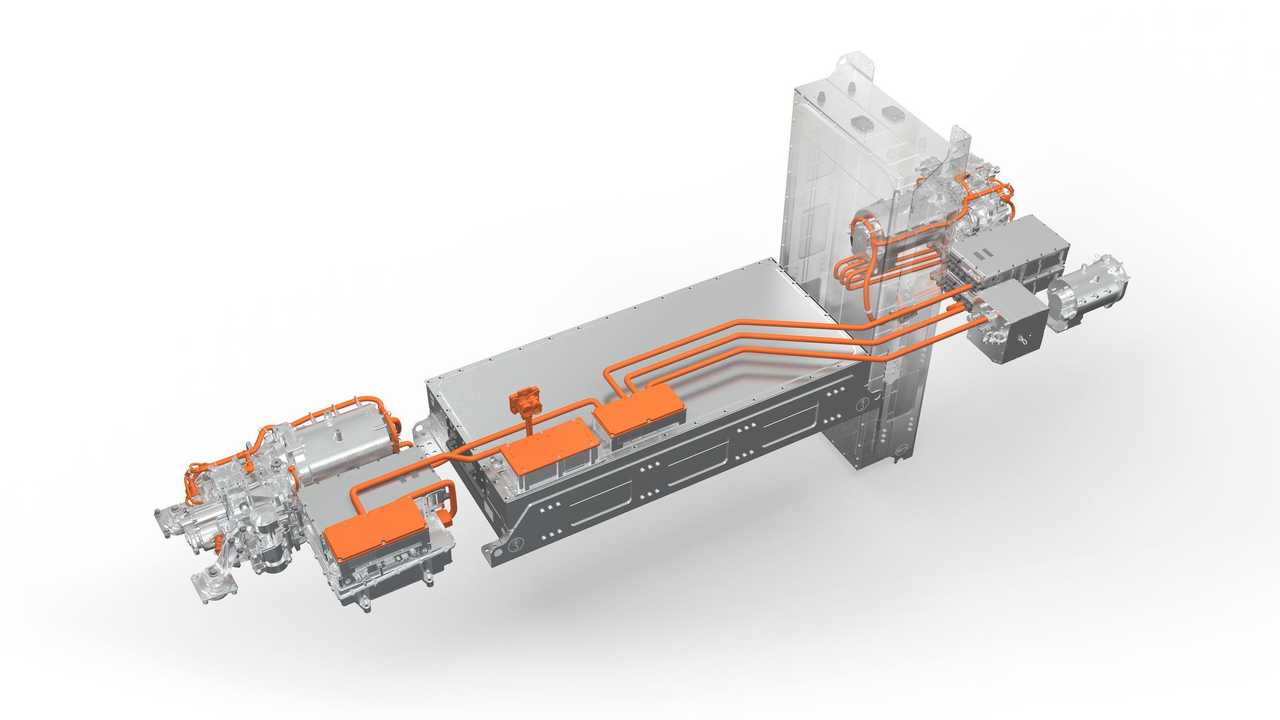

"Unlike other Volvo Group EVs that might have two or sometimes three electric machines, the RT required four to do its job. All four electric machines have to be able to run simultaneously – two for propulsion, one for the range extender to provide extra battery power, and one for electric power takeoff, if fire-fighters want to rotate the foam pump for example. To achieve this, the Volvo Penta engineers created a system that is completely cutting edge in terms of Volvo Group technology."

"Due to the required compact dimensions of a city fire truck, Volvo Penta created a new Active Cooling Unit (ACU). This component was developed in part collaboration with Rosenbauer. The new ACU draws on a 600V system – instead of the conventional 24V – this extra power allows Volvo Penta to not only cool the batteries but also offer cooling capacity to the Rosenbauer vehicle. This is one way Volvo Penta has optimized the design and adapted the complete electric driveline system for a specific vehicle, considering the exact application, usage, climate, and environment it will operate in."

So far, only a few units were built and entered pilot service in Berlin, Amsterdam, and Dubai, as well as were demonstrated around the world, including in the U.S.

It will be very interesting how well the electric fire trucks will cope in the real world as it's a much more demanding application than an ordinary electric truck. This is also why there is still an onboard diesel generator.

Rosenbauer’s electric fire truck “Revolutionary Technology” (RT) specs:

- 50 kWh battery pack (standard, 550 kg) or 100 kWh (option)

- Volvo Penta electric driveline

- dual motor all-wheel drive (one electric motor per axle, with two-speed gearbox each)

- system output of up to 360 kW (490 HP) and up to 50,000 Nm for all wheels

a six-cylinder diesel engine with an output of 200 kW (272 HP) and a power generator - DC fast charging at up to 150 kW (50-80% in one hour in the case of 100 kWh version)

- power export feature of up to 18 kW

- 2.35 m wide and 7.30 m long with a wheelbase of 3,800 m (also available with wheelbases of 4,100 mm and 4,400 mm), height is 2.90 m

- total weight of 18 tons

SOURCE: INSIDEEVs

Mantsinen Dualpower combines electric, diesel motors

The Mantsinen Dualpower material handler promises mobility, productivity and environmental friendliness.

July 9, 2021

The Mantsinen Dualpower material handler combines what the manufacturer says are the best features of electric and diesel engines, resulting in mobility, productivity and environmental friendliness.

Swedish company Engbergs Transportsystem AB operates at Östrand pulp mill, near the Sundsvall port on the Swedish east coast. The company is offloading of round wood and woodchips and also has started handling bark. Engbergs has a long history with Mantsinen Group.

Kjell Arne Engberg, CEO of Engbergs, says, “Our relationship with Mantsinen has deepened during the years. In 2003, our first Mantsinen machine was put to use, and we were very satisfied with the machine, not to mention the service support we got. No ma tter where in the world our contact was, they always answered the phone.”

In 2017, Engbergs began discussing Mantsinen’s latest innovation, the Dualpower material handler, with the manufacturer. Engbergs was the first customer to acquire a Mantsinen’s Dualpower machine: a Mantsinen 120 with crawler gantry undercarriage.

“I am very open-minded towards development of new technology,” Engberg says. “We purchased one diesel Mantsinen 120 and one Mantsinen 120 with Dualpower. The reason for the machine renewal l was that the pulp mill decided to increase production by 100 percent, and we needed to solve the logistics accordingly. In all our investments, we look into the possibility of reducing carbon emissions. We wanted this solution because it combines two benefits: when you reduce emissions, you also reduce costs. It is a win-win situation. However, we still needed a diesel-driven machine too, because we could not access electrical power all around the pulp mill area. The pulp mill was luckily very interested in helping us build the power grid solution.”

One of the benefits of the Dualpower material handler is easy maintenance, the manufacturer says. The technology is based on standard components, allowing easy service and normal spare parts availability. Pairing this technology with the Mantsinen Insight remote monitoring system allows smooth operation and fewer unexpected surprises, Mantinsen says.

The material handler works well, and it has reduced the need for maintenance,” Engberg says. He adds, “The Mantsinen Insight lets the machine tell you if something is not right. In the future, I think we could even solve some problems remotely and not on the site.”

In addition to maintenance needs, the Mantsinen Insight also records important data on performance and efficiency. Engbergs has achieved the production increase it wanted with the help of the Mantsinen 120 Dualpower.

“Looking at the last 7 days, we have lifted 23 000 [metric tons] mainly running on electric motor. Our production has been in average 435 [metric tons] per hour.”

He adds, “It seems this material handler with both diesel and electric drive is the right solution for us. We have reduced the emissions enormously.”

https://www.recyclingtoday.com/article/mantsinen-dualpower-material-handler/